- Asia

-

대한민국 / Korean

대한민국 / Korean

中国 / Chinese

中国 / Chinese

Bangladesh / English --%>

Bangladesh / English --%>

- Middle East

-

Türkiye / Turkish

Türkiye / Turkish

- Europe

-

Germany / German

Germany / German

Poland / Polish

Poland / Polish

- North America

-

USA / English

USA / English

Search for the product or information you are interested in.

- My Search History

- Recommended Search Terms

- Electronic Balance

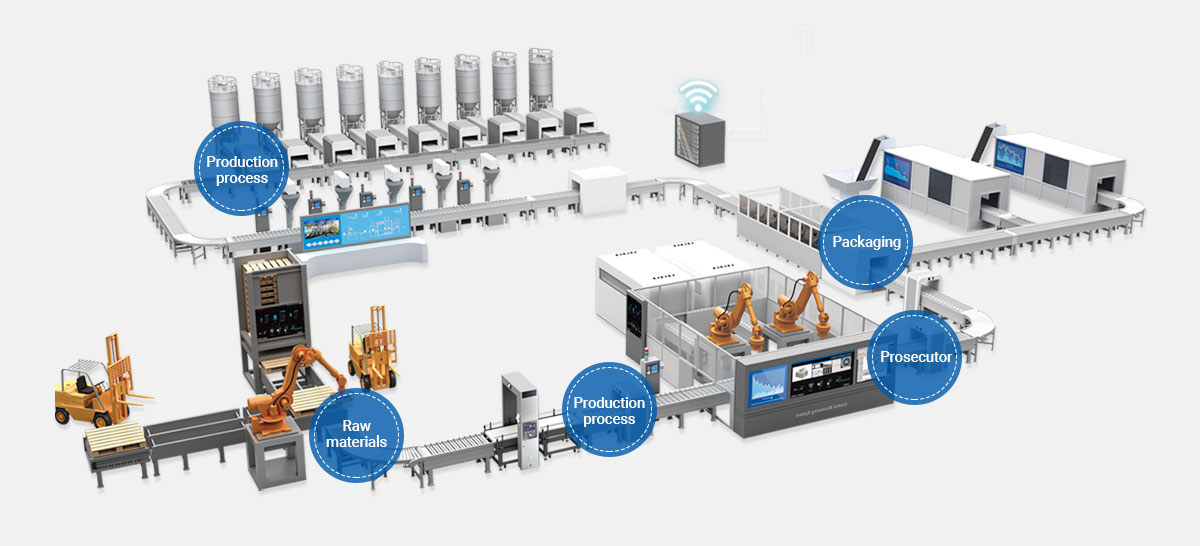

POP(point of production) Management System

This is a system that can aggregate, analyze, and query the information generated at the production site in real time.

Active data communication with relevant departments is enabled through real-time monitoring.

In addition, it is possible to collect high-quality data, enabling data tracing and analysis.

Warehouse Manager

Production Manager

Control Room

Solution

-

Raw material blending solution

Precise formulation and discharge of raw materials -

Auto Recognition Equipment Solution

Digitalization of

history management -

Powder Packaging Solution

Automation of processes

from powder input to

packaging and transport -

Liquid Filling Solution

Automation of processes

from liquid filling to

packaging and transport

Expected effects

Increased productivity : Increases the productivity of the factory through improved work efficiency

Quality improvement : Improves productivity and quality by automating tasks that are repetitive and exhausting, or for which it is difficult to secure objective data.

Traceability : Traceability supported through active information exchange between departments, enabling the identification and analysis of the accident causes

고객센터

고객센터

고객센터

고객센터

TOP

TOP